Built by Diamond: Outfitting North Dakota’s Hardest-Working Trucks

Introduction: Real Work Needs Real Equipment

In Western North Dakota, your trucks aren’t just vehicles — they’re your livelihood. Between oil field routes, harsh winters, and endless hours in the elements, every component on your rig has to perform perfectly.

That’s why Diamond specializes in custom hydraulic systems, PTO setups, snow plows, air compressors, and full-service accessory installs built for real work. From wiring work lights to installing decked units and plow systems, we make sure your trucks are ready to work as hard as you do.

1. Hydraulics and PTO Systems: The Power Behind the Job

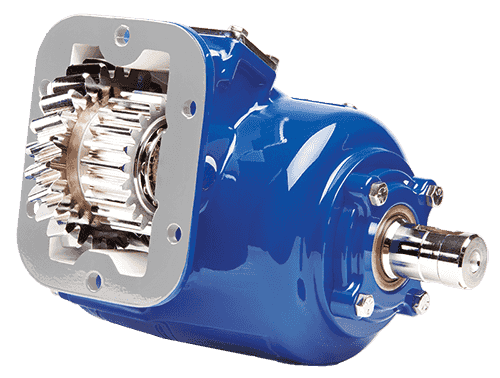

Power take-off (PTO) and hydraulic systems drive the toughest field jobs — from running cranes to powering liftgates. But when they’re neglected, downtime and costly damage follow.

A study by the National Institute for Automotive Service Excellence (ASE) found that nearly 40% of hydraulic failures come from improper installation or fluid maintenance errors.

Diamond’s hydraulic and PTO services include:

PTO installation and repair for service trucks and semis.

Hydraulic pump setup, hose replacement, and diagnostics.

System pressure testing and leak detection.

Preventative fluid and seal maintenance for optimal performance.

Properly maintained hydraulic systems can last 25–30% longer, saving fleets thousands in unplanned repairs.

2. Air Compressor Systems: Clean Air, Clean Operation

Air compressors are the unsung heroes of service fleets — powering tools, lifts, and emergency systems. Neglecting them costs more than most operators realize.

According to Fleet Equipment Magazine, air compressor downtime can cause up to a 15% loss in productivity for service trucks operating in the field.

Diamond’s compressor maintenance and installation services include:

Safety checks.

Custom mounting and rewiring for decked or enclosed service bodies.

Routine compressor service improves system efficiency by up to 20%, lowering fuel use and extending tool life.

3. Snow Plows and Winter Equipment

When the Bakken winter hits, reliability becomes survival. Research from the U.S. Department of Transportation shows that each hour of snow plow downtime costs $300–$700 in labor and lost productivity.

Diamond keeps your winter equipment running strong with:

Hydraulic and electrical diagnostics for plow lift and angle systems.

Seasonal inspection programs that prepare for the first freeze.

Corrosion-resistant coatings and bed liners to protect against salt and brine.

Adding a protective liner can reduce corrosion-related damage by up to 60%, extending truck bed and frame life through harsh North Dakota winters.

4. Accessories and Custom Outfitting: Built Around Your Workflow

Every operator works differently — and your truck should reflect that.

Diamond’s custom outfitting includes:

Lighting: wiring strobes, compartment lighting, and work lamps.

Storage: installing drawer units, Decked systems, and lockable compartments.

Hauling: drop axle installs, tarp systems, load straps, and chain mounts.

Protection: toppers, full/half/quarter fenders, and reinforced guards.

A study by the National Association of Fleet Administrators (NAFA) found that organized, outfitted service vehicles reduce field time by up to 25% through better tool access and workflow efficiency.

5. Bed Liners & Corrosion Protection

Salt, brine, and heavy use can eat through steel faster than most realize. The National Association for Corrosion Engineers (NACE) estimates that corrosion costs U.S. fleets more than $9 billion annually in damage and downtime.

Diamond’s spray-in bed liners and undercoating services add a durable, chemical-resistant barrier that prevents rust, extends your truck’s lifespan, and keeps your investment working for years.

6. Why Fleets Choose Diamond

Diamond is trusted across Western North Dakota because we combine technical precision with real-world experience. From hydraulics to lighting, every installation is built to last, field-tested, and backed by local expertise.

We understand:

Extreme temperature swings

Heavy-duty hydraulic demands

Electrical integration challenges

Preventative service scheduling

When it says Built by Diamond, it means engineered for endurance, reliability, and performance — built right here in North Dakota.

Schedule your Hydraulic, PTO, or Custom Accessory Install today — proudly serving Williston, Watford City, Dickinson, and all of Western North Dakota.

Because when your equipment works harder, so can you.

Sources

National Institute for Automotive Service Excellence (ASE), Hydraulic System Maintenance Report, 2021.

Eaton Hydraulics, Hydraulic Lifecycle Management Study, 2020.

Fleet Equipment Magazine, The Cost of Air System Downtime, 2019.

Ingersoll Rand, Compressor Maintenance Efficiency Data, 2020.

U.S. Department of Transportation, Winter Maintenance Cost Study, 2022.

Corrosion Prevention Council, Protective Coatings for Fleet Equipment, 2021.

National Association of Fleet Administrators (NAFA), Service Vehicle Efficiency Study, 2019.

National Association for Corrosion Engineers (NACE), Corrosion Costs and Preventive Strategies Study, 2020.